The performance and reliability of modern RF and microwave components, such as filters, diplexers, and amplifiers, are fundamentally underpinned by their packaging materials. A recent industry analysis provides a clear comparison of the three dominant ceramic substrate materials—Alumina (Al₂O₃), Aluminum Nitride (AlN), and Silicon Nitride (Si₃N₄)—each serving distinct market segments based on a performance-to-cost ratio.

Material Breakdown & Key Applications:

Alumina (Al₂O₃): The established, cost-effective solution. With a thermal conductivity of 25-30 W/(m·K), it dominates price-sensitive applications like consumer electronics and standard LED lighting, holding over 50% of the market.

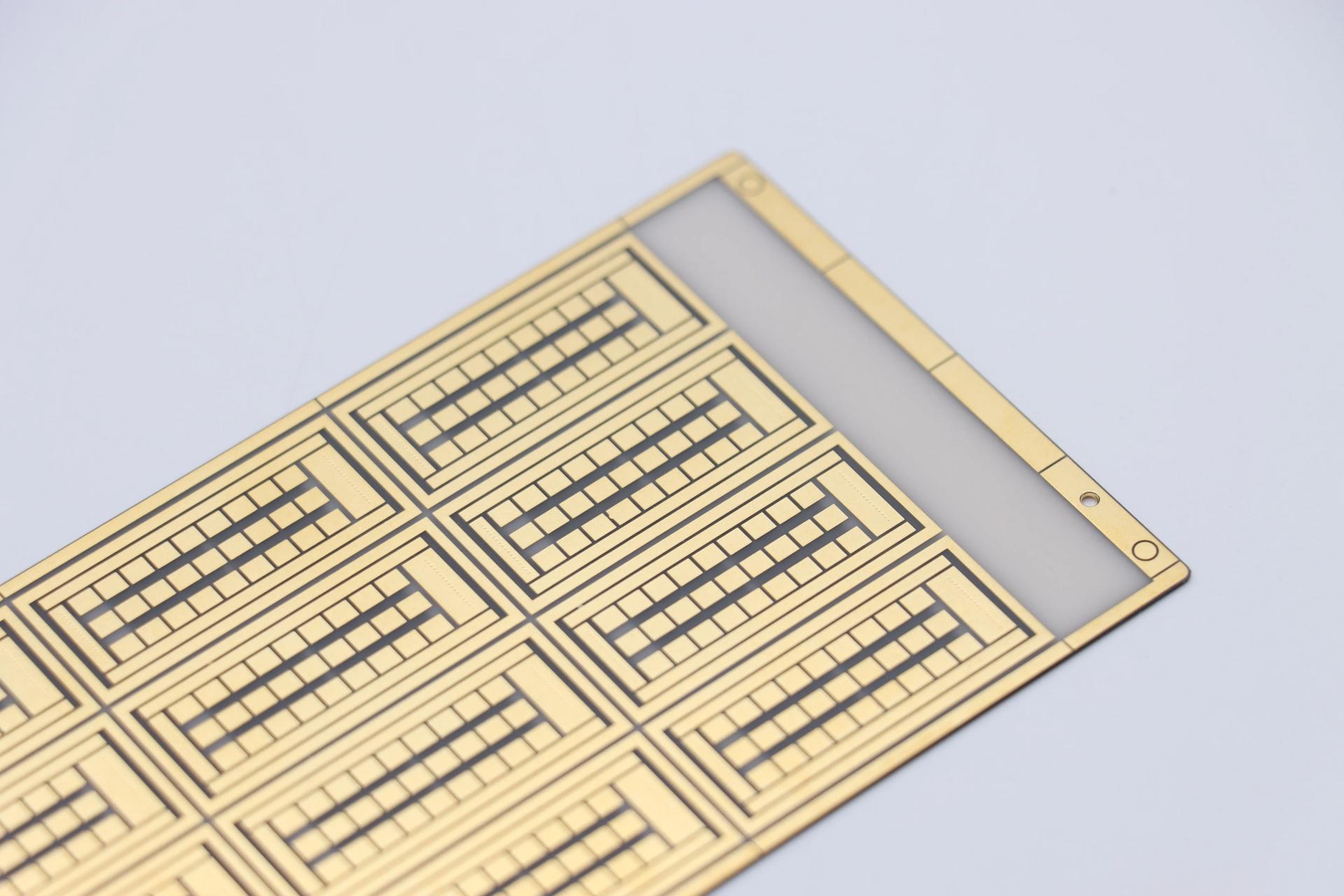

Aluminum Nitride (AlN): The preferred choice for high-frequency and high-power scenarios. Its exceptional thermal conductivity (200-270 W/(m·K)) and low dielectric loss are critical for dissipating heat and maintaining signal integrity in 5G base station power amplifiers and advanced radar systems.

Silicon Nitride (Si₃N₄): The high-reliability champion. Offering the best mechanical strength and excellent thermal shock resistance, it is indispensable for mission-critical applications under extreme stress, such as in aerospace and next-generation electric vehicle power modules.

At Concept Microwave, we deeply understand this material science foundation. Our expertise in designing and manufacturing high-performance passive microwave components, including cavity filters, diplexers, and custom assemblies, is built upon selecting the optimal materials like AlN or Si₃N₄ substrates. This ensures our products deliver the necessary thermal management, signal purity, and long-term reliability required for demanding applications in telecommunications, satellite, and defense systems.

Post time: Jan-30-2026