The limitations of power dividers in high-power combining applications can be attributed to the following key factors:

1. Power Handling Limitations of the Isolation Resistor (R)

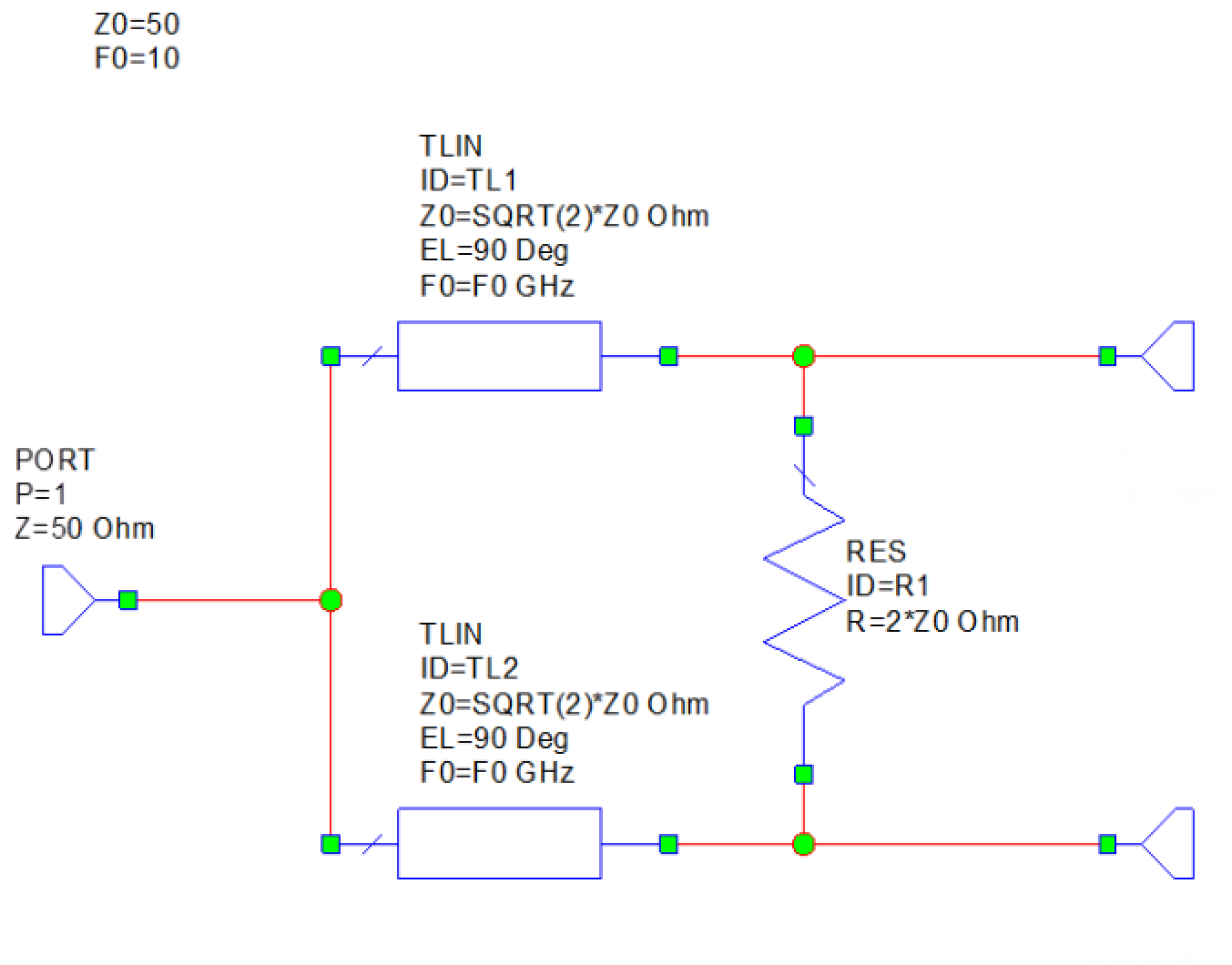

- Power Divider Mode:

- When used as a power divider, the input signal at IN is split into two co-frequency, co-phase signals at points A and B.

- The isolation resistor R experiences no voltage difference, resulting in zero current flow and no power dissipation. The power capacity is determined solely by the microstrip line’s power-handling capability.

- Combiner Mode:

- When used as a combiner, two independent signals (from OUT1 and OUT2) with different frequencies or phases are applied.

- A voltage difference arises between A and B, causing current flow through R. The power dissipated in R equals ½(OUT1 + OUT2). For example, if each input is 10W, R must withstand ≥10W.

- However, the isolation resistor in standard power dividers is typically a low-power component with inadequate heat dissipation, making it prone to thermal failure under high-power conditions.

2. Structural Design Constraints

- Microstrip Line Limitations:

- Power dividers are often implemented using microstrip lines, which have limited power-handling capacity and insufficient thermal management (e.g., small physical size, low heat dissipation area).

- The resistor R is not designed for high-power dissipation, further restricting reliability in combiner applications.

- Phase/Frequency Sensitivity:

- Any phase or frequency mismatch between the two input signals (common in real-world scenarios) increases power dissipation in R, exacerbating thermal stress.

3. Limitations in Ideal Co-Frequency/Co-Phase Scenarios

- Theoretical Case:

- If two inputs are perfectly co-frequency and co-phase (e.g., synchronized amplifiers driven by the same signal), R dissipates no power, and the total power is combined at IN.

- For example, two 50W inputs could theoretically combine into 100W at IN if the microstrip lines can handle the total power.

- Practical Challenges:

- Perfect phase alignment is nearly impossible to maintain in real systems.

- Power dividers lack robustness for high-power combining, as even minor mismatches can cause R to absorb unexpected power surges, leading to failure.

4. Superiority of Alternative Solutions (e.g., 3dB Hybrid Couplers)

- 3dB Hybrid Couplers:

- Utilize cavity structures with external high-power load terminations, enabling efficient heat dissipation and high power-handling capacity (e.g., 100W+).

- Provide inherent isolation between ports and tolerate phase/frequency mismatches. Mismatched power is safely diverted to the external load rather than damaging internal components.

- Design Flexibility:

- Cavity-based designs allow for scalable thermal management and robust performance in high-power applications, unlike microstrip-based power dividers.

Conclusion

Power dividers are unsuitable for high-power combining due to the isolation resistor’s limited power-handling capacity, inadequate thermal design, and sensitivity to phase/frequency mismatches. Even in ideal co-phase scenarios, structural and reliability constraints make them impractical. For high-power signal combining, dedicated devices like 3dB hybrid couplers are preferred, offering superior thermal performance, tolerance to mismatches, and compatibility with cavity-based high-power designs.

Concept offers full range of passive microwave components for military , Aerospace, Electronic Countermeasures, Satellite Communication, Trunking Communication applications : Power divider , directional coupler , filter , duplexer , as well as LOW PIM components up to 50GHz , with good quality and competitive prices.

Welcome to our web: www.concept-mw.com or reach us at sales@concept-mw.com

Post time: Apr-29-2025