Overview

LTCC (Low-Temperature Co-Fired Ceramic) is an advanced component integration technology that emerged in 1982 and has since become a mainstream solution for passive integration. It drives innovation in the passive component sector and represents a significant growth area in the electronics industry

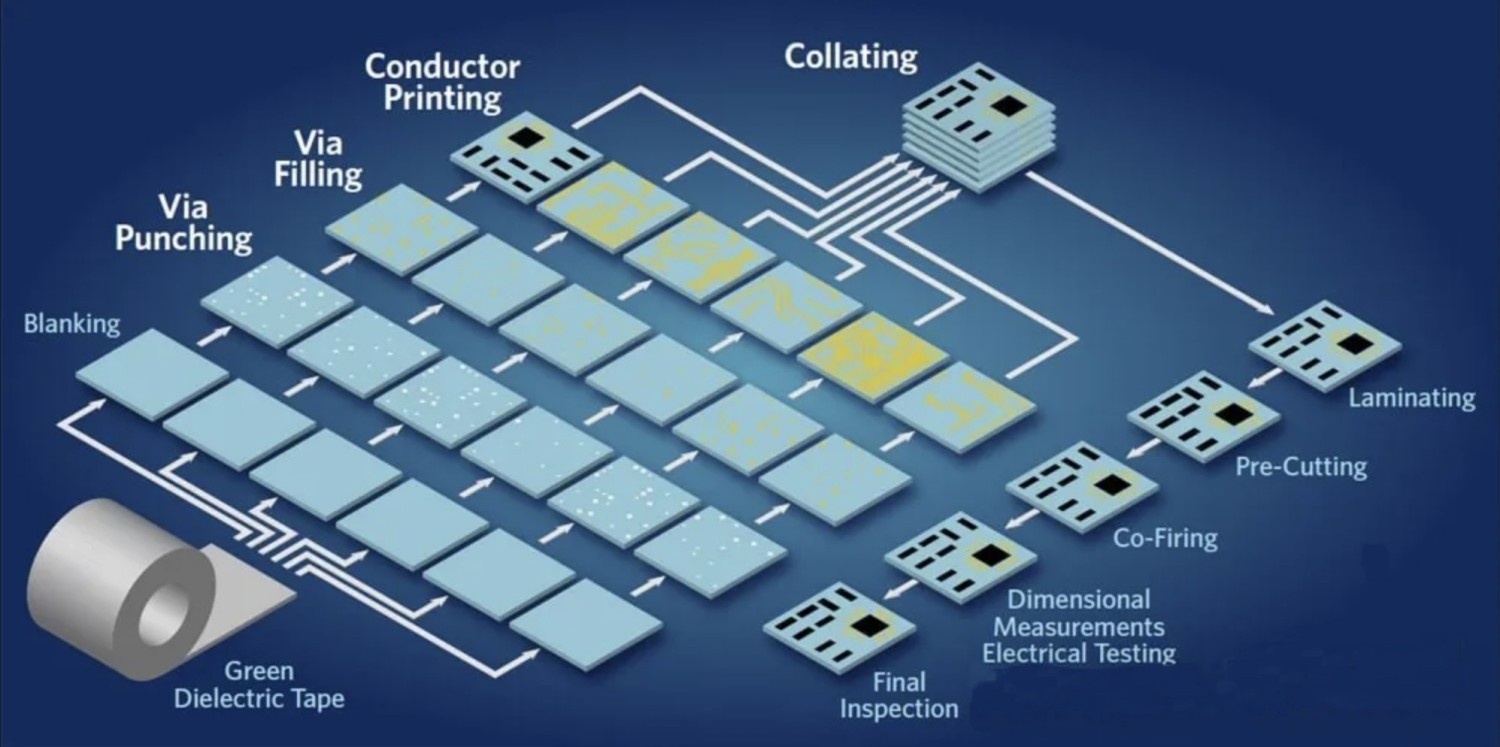

Manufacturing Process

1.Material Preparation: Ceramic powder, glass powder, and organic binders are mixed, cast into green tapes via tape casting, and dried23.

2.Patterning: Circuit graphics are screen-printed onto the green tapes using conductive silver paste. Pre-printing laser drilling may be performed to create interlayer vias filled with conductive paste23.

3.Lamination and Sintering: Multiple patterned layers are aligned, stacked, and thermally compressed. The assembly is sintered at 850–900°C to form a monolithic 3D structure12.

4.Post-Processing: Exposed electrodes may undergo tin-lead alloy plating for solderability3.

Comparison with HTCC

HTCC (High-Temperature Co-Fired Ceramic), an earlier technology, lacks glass additives in its ceramic layers, requiring sintering at 1300–1600°C. This limits conductor materials to high-melting-point metals like tungsten or molybdenum, which exhibit inferior conductivity compared to LTCC’s silver or gold34.

Key Advantages

1.High-Frequency Performance: Low dielectric constant (ε<sub>r</sub> = 5–10) materials combined with high-conductivity silver enable high-Q, high-frequency components (10 MHz–10 GHz+), including filters, antennas, and power dividers13.

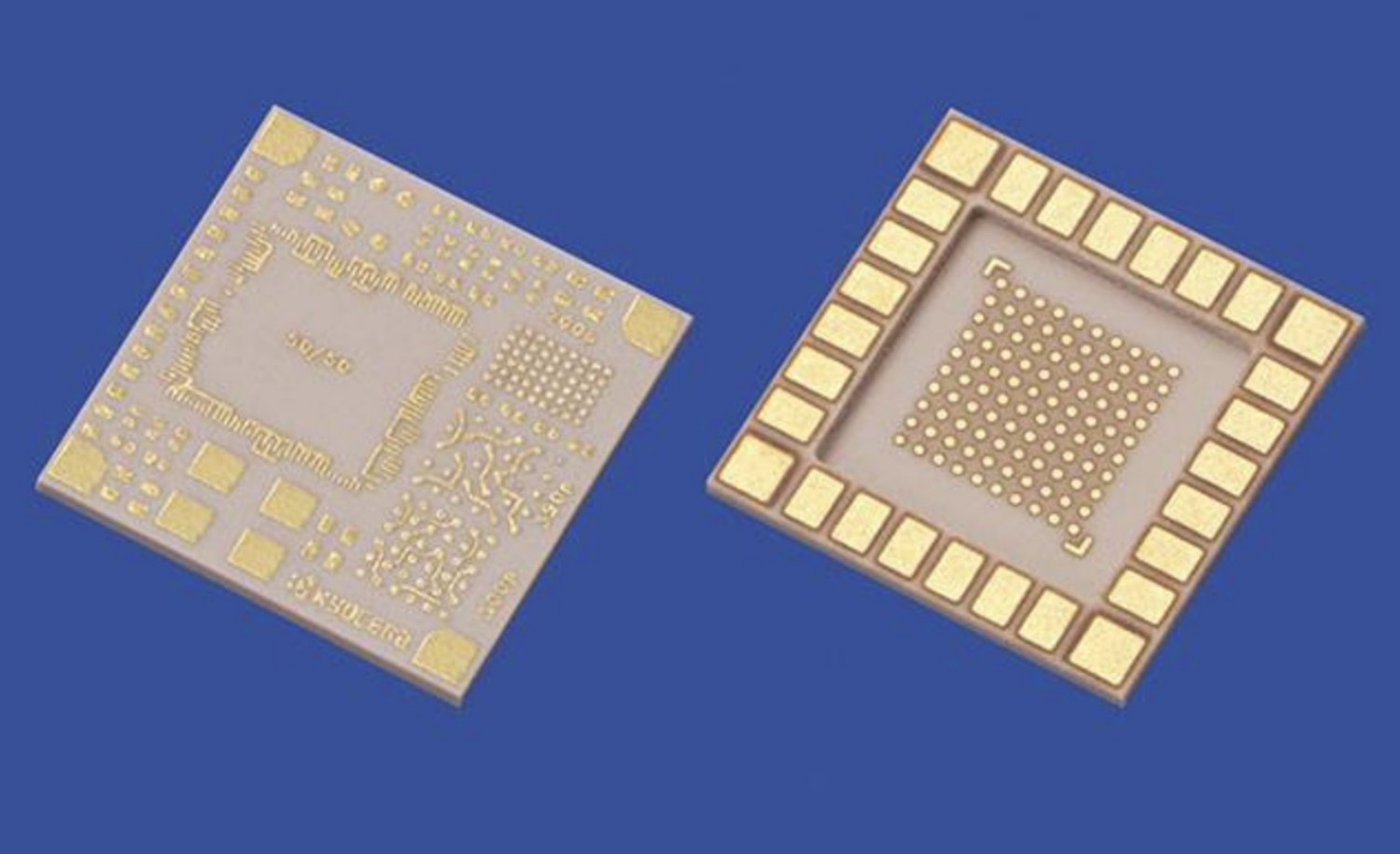

2.Integration Capability: Facilitates multilayer circuits embedding passive components (e.g., resistors, capacitors, inductors) and active devices (e.g., ICs, transistors) into compact modules, supporting System-in-Package (SiP) designs14.

3.Miniaturization: High-ε<sub>r</sub> materials (ε<sub>r</sub> >60) reduce footprint for capacitors and filters, enabling smaller form factors35.

Applications

1.Consumer Electronics: Dominates mobile phones (80%+ market share), Bluetooth modules, GPS, and WLAN devices

2.Automotive and Aerospace: Increasing adoption due to high reliability in harsh environments

3.Advanced Modules: Includes LC filters, duplexers, baluns, and RF front-end modules

Chengdu Concept Microwave Technology CO.,Ltd is a professional manufacturer of the 5G/6G RF components in China , including the RF lowpass filter , highpass filter , bandpass filter , notch filter/band stop filter , duplexer,Power divider and directional coupler . All of them can be customized according to your requrements .

Welcome to our web :www.concept-mw.com or reach us at:sales@concept-mw.com

Post time: Mar-11-2025